Wireless Remote Monitoring Solutions

Equipment Monitoring Solutions

Answer critical questions about equipment, machinery, and the environment with wireless IoT sensors from Atomation

Atoms are a better way to capture the information you need to know – whether it’s the temperature of the bearing, the impact on the dragline or the preventive maintenance needed on a motor, Atoms answer the critical questions that mean the success or failure of your operations.

- rTrigger-based solution customizable at the device level

- Wireless communication direct to cloud or via gateway

- View information via dashboard or through our open API

Get the answers you need to know to improve operations across your organization.

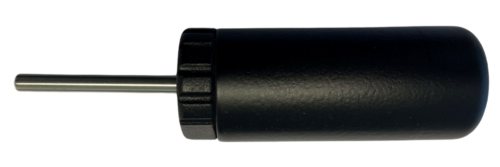

NEW! External Temperature Probe for Bearing Monitoring

The latest innovation from the Atomation product team is the perfect choice for your bearing temperature monitoring needs.

Out-of-the-Box Application Across Industries

No infrastructure. No wiring. Immediately operational.

Capture the information you need to act on in the field, on the manufacturing floor, at the pump, on the tower, or anywhere that automated data capture and trigger-based warnings would benefit your operations.

Because Atoms are an all-in-one sensing solution, the same Atom is used across a variety of industries and applications.

Case Studies

FEATURED USE CASE

Bearing & Motor Monitoring

Problem

Shaker tables are a key component of many manufacturing processes. When the springs wear out or begin to fail, the shaker table begins to behave erratically, sometimes throwing things (in this case, rocks!) off the table, resulting in a safety hazard as well as a downed line while the springs and the table are repaired.

Solution

Atoms were installed on all four springs, detecting when the springs began to exhibit signs of fatigue prior to failure.

An Atom with an external temperature sensor was installed to monitor bearing temperatures.

Result

Atoms were more than up to the task in this harsh environment and performed flawlessly immediately after installation. Atoms detected minor changes in spring vibration that gave the team sufficient information to infer when a spring was about to fail. Analysis of normal operation across multiple devices allowed operators to see when one device was not operating in the same fashion as other, similar devices.

Increases in bearing temperature gave the team an immediate alert, to go and inspect the shaker, providing a simple method for bearing and motor monitoring.

Bonus

Sometimes Atoms deliver insights that are not expected! The user expected that when the table was in operation without a load, bearing temperature would be lower. This was not the case. The temperature actually increased when the table was operated without anything on the table. This finding, validated over several weeks of operation, led the manufacturer to completely revamp their maintenance program.

They created a new inspection procedure to improve shaker maintenance based on this finding. Now they are using Atoms to correlate bearing temperature with materials being manufactured. This lets them improve overall performance and better understand the maintenance needs of the motor.

More Use Cases

How It Works

2022 IoT Innovator Finalist Award